Tesla to expand lithium refining capacity to meet growing demand for EV batteries

05/02/2023 / By Laura Harris

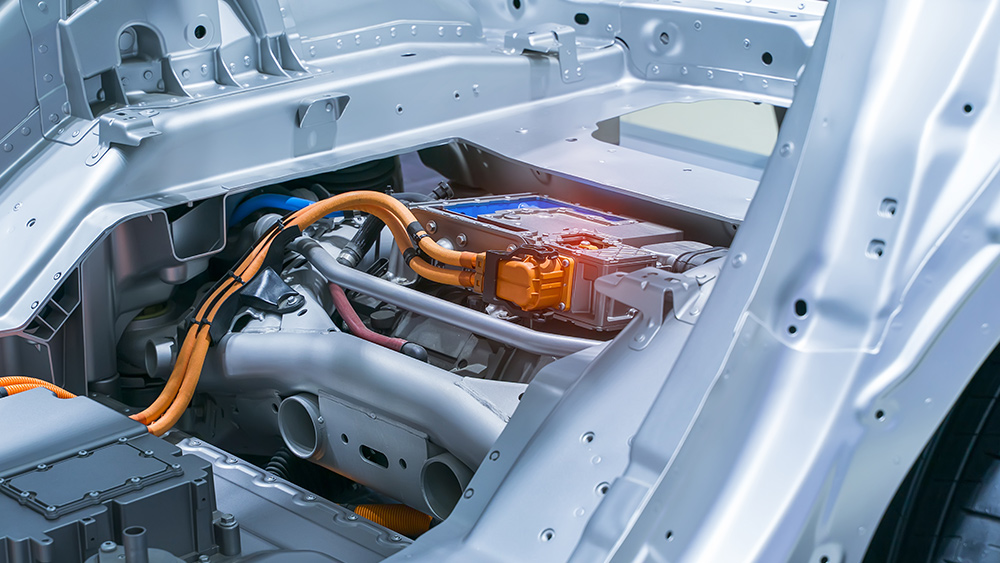

Electric vehicle (EV) manufacturer Tesla plans to expand its lithium refining capacity in response to the increasing demand for EV batteries.

According to the latest report published by Utility Dive on April 28, Tesla’s first-quarter earnings highlighted its intention to boost its lithium refining capacity despite increasing mineral prices. As the demand for EVs increases worldwide, the market for lithium-ion batteries has skyrocketed as well.

However, limited lithium refining capacity and fluctuating mineral prices have posed challenges to EV battery production. Tesla has recognized the need to support its in-house refining capabilities to ensure the long-term sustainability of its EV production.

This strategic move cemented Tesla’s position as the leader in EV market, capable of scaling up production to meet the needs of a rapidly expanding customer base.

Tesla’s support for the lithium supply chain is expected to significantly impact the EV industry. The company can mitigate the risks associated with supply chain disruptions and price fluctuations by ensuring a stable and cost-effective lithium supply. This, in turn, helps in the mass production of EV batteries and accelerates the global transition to EVs.

6M EV battery packs to end up as scrap between now and 2030

In partnership with industry stakeholders, the U.S. government has initiated efforts to increase lithium extraction and the country’s processing capabilities by developing domestic sources of lithium, expanding lithium refining facilities and incentivizing research and development in battery technologies.

However, insufficient refining capacity could hinder the recycling process and exacerbate the environmental impact of battery waste. There are also potential hazards associated with retired electric car batteries. These batteries can contain toxic materials and pose a risk of fire or explosion if mishandled. The lack of standardized protocols for the safe disposal and recycling of these batteries raises concerns about their proper management and the potential risks to public safety and the environment. (Related: Ticking time bombs: Biden administration does not have a concrete plan for recycling or reusing EV battery packs.)

While efforts are being made to address these challenges, including increased investment in recycling technologies and developing policies for responsible battery disposal, much work remains to be done. Governments, car manufacturers and recycling companies are grappling with the scale and complexity of the battery waste issue.

The recycling and reuse industries are scrambling to keep pace as over six million EV battery packs are expected to end up as scrap between now and 2030. Researchers have estimated that recycling alone will be a $12 billion industry by 2025.

The urgency to find sustainable solutions to this growing problem is evident. The safe and efficient recycling of retired electric car batteries is crucial not only for environmental reasons but also to recover valuable materials, reduce dependence on mining and mitigate supply chain risks.

As the electric vehicle industry continues to evolve and EV adoption accelerates, stakeholders need to collaborate and invest in developing efficient recycling processes, expanding refining capacity, and implementing comprehensive regulations for battery waste management. Only through proactive actions can the industry effectively address the challenges posed by the millions of electric car batteries retiring in the coming years.

Visit RoboCars.news for more news related to electric vehicles.

Watch this video to learn more about how EV cars, lithium-ion battery tech and solar power work together.

This video is from the Off-Grid Solar channel on Brighteon.com.

More related stories:

New Lithium Nanowire Technology Boosts Lithium Ion Battery Capacity by 1000 Percent.

EV maker Tesla looking to set up lithium refinery in Texas, eyes tax relief.

Sources include:

Submit a correction >>

Tagged Under:

battery disposal, battery waste, car manufacturers, ecology, electric cars, Elon Musk, environment, Essential Minerals, EV, EV battery production, green living, Green New Deal, lithium, lithium refining capacity, lithium supply chain, mining, recycling, tesla

This article may contain statements that reflect the opinion of the author

RECENT NEWS & ARTICLES

COPYRIGHT © 2017 ELON MUSK WATCH